Bombay Machine Tools

Used Machinery Dealer In Bhosari

Hello Sir

Thursday, 20 December 2018

Friday, 14 December 2018

Used Cincinati Tool And Cutter at Bhosari Yash Enterprises, Bombay Machine Tools.

Monday, 22 October 2018

Used Machinery | Second Hand Machinery | Imported Milling , Surface Grinder , Radial Drill | Bombay Machine Tools | Yash Enterprises | Bhosari

Shoblin milling 700×300×450 pRICE= 240k

Shoblin milling 700×300×450 pRICE= 240k

Pillar drill 1. 5" pRICE= 22k

Pillar drill 1. 5" pRICE= 22k

Indian 4.5" feet lathe Price = 18k

Indian 4.5" feet lathe Price = 18k

Cincinati milling 900×400×600 Price =340k

Cincinati milling 900×400×600 Price =340k

Cugir milling universal ISO 50 700×350×400 Price= 240k

Cugir milling universal ISO 50 700×350×400 Price= 240k

Batliboi VVR5 50" Hydraulic clamp Price =370k

Batliboi VVR5 50" Hydraulic clamp Price =370k

Fritz vernier milling 1200×400×350 Price= 240k

Fritz vernier milling 1200×400×350 Price= 240k

Jockbson 300×600 hydraulic Price = 340k

Jockbson 300×600 hydraulic Price = 340k

Hmt Radial drill 50" Price = 240k

Hmt Radial drill 50" Price = 240k

Ernoult surface 200×600× hydraulic Price=270k

Ernoult surface 200×600× hydraulic Price=270k

Elge compressor 10hp Price= 65k

Elge compressor 10hp Price= 65k

Saturday, 13 October 2018

Industrial commercial property for sale and rent , Pune nashik highway chimbali Phata barge wasti

#Rent 20000 Sqft Rs. 6 per Sq.ft

#Sale Price Rs. 7 Lakh per Guntha

Pune Nashik Highway Distance 500 miters

Anyone interested For JV Then feel free contact with us

All Documents clear and available

#Rent 20000 Sqft Rs. 6 per Sq.ft

#Sale Price Rs. 7 Lakh per Guntha

Pune Nashik Highway Distance 500 miters

Anyone interested For JV Then feel free contact with us

All Documents clear and available

Friday, 23 February 2018

Monday, 27 November 2017

Machine Operation About | Used Machinery dealer | Bombay Machine Tools | Bhosari

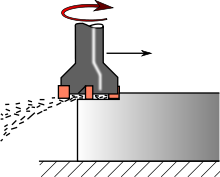

Milling (machining)

Process[edit]

- In face milling, the cutting action occurs primarily at the end corners of the milling cutter. Face milling is used to cut flat surfaces (faces) into the workpiece, or to cut flat-bottomed cavities.

- In peripheral milling, the cutting action occurs primarily along the circumference of the cutter, so that the cross section of the milled surface ends up receiving the shape of the cutter. In this case the blades of the cutter can be seen as scooping out material from the work piece. Peripheral milling is well suited to the cutting of deep slots, threads, and gear teeth.

Milling cutters[edit]

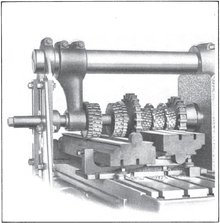

Gang milling[edit]

Surface grinding

Process[edit]

Equipment[edit]

Types of surface grinders[edit]

Horizontal-spindle (peripheral) surface grinders[edit]

Vertical-spindle (wheel-face) grinders[edit]

Disc grinders and double-disc grinders.[3][edit]

Grinding wheels for surface grinders[edit]

Lubrication[edit]

Jig borer

History[edit]

- coordinate dimensioning (dimensioning of all locations on the part from a single reference point);

- working routinely in "tenths" (ten-thousandths of an inch, 0.0001 inch) as a fast, everyday machine capability (whereas it had been the exclusive domain of special, time-consuming, craftsman-dependent manual skills); and

- circumventing jigs altogether.

Subscribe to:

Comments (Atom)