Milling (machining)

Process[edit]

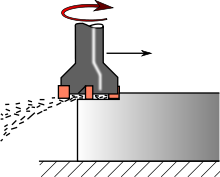

- In face milling, the cutting action occurs primarily at the end corners of the milling cutter. Face milling is used to cut flat surfaces (faces) into the workpiece, or to cut flat-bottomed cavities.

- In peripheral milling, the cutting action occurs primarily along the circumference of the cutter, so that the cross section of the milled surface ends up receiving the shape of the cutter. In this case the blades of the cutter can be seen as scooping out material from the work piece. Peripheral milling is well suited to the cutting of deep slots, threads, and gear teeth.

Milling cutters[edit]

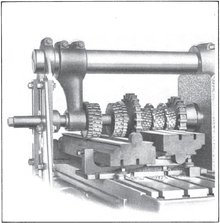

Gang milling[edit]

Surface grinding

Process[edit]

Equipment[edit]

Types of surface grinders[edit]

Horizontal-spindle (peripheral) surface grinders[edit]

Vertical-spindle (wheel-face) grinders[edit]

Disc grinders and double-disc grinders.[3][edit]

Grinding wheels for surface grinders[edit]

Lubrication[edit]

Jig borer

History[edit]

- coordinate dimensioning (dimensioning of all locations on the part from a single reference point);

- working routinely in "tenths" (ten-thousandths of an inch, 0.0001 inch) as a fast, everyday machine capability (whereas it had been the exclusive domain of special, time-consuming, craftsman-dependent manual skills); and

- circumventing jigs altogether.